Specialist – Roll Form Machines & Systems

New and Rebuilt Roll Formers

FPE can design and build Your Roll forming System from the ground up or rebuild your current machines for a new application. FPE can take a used roll form system and customize it for your needs. In all cases you benefit from our 50 years of combined experience in Engineering & Fabricating Rollforming Equipment. We supply solutions to the Building Construction market, commercial markets and for industrial applications. In many cases we can build a custom roll former for less than a competitors standard model. All our systems use off the shelf components for construction. Allowing for easy maintenance whenever it may be needed.

With over 50 years experience with roll forming we have seen it all.

Let us help you with your next project or troubleshoot an existing problem.

- Design for application

- Turnkey Fabrication

- Research and implement new production lines

- Troubleshoot existing lines and machinery

- Retrofit and upgrades

- System assembly and disassembly

- Maximize tooling use

- Tolerances issues

- Maximize production rates

- Minimize scrap

- Installation and start-up service

- Onsite training

Videos of Custom Roll Form Equipment

Stiffener Stud Rollforming System with attached in-line punch and flying cut-off

Testing Beam Rollforming System

Members of the Form Process Engineering team testing the Elevations Roll forming System. 10 foot long pieces at a production speed of 85 feet per minute.

Drywall Stud Roll Former

System has side by side tooling to make drywall stud, drywall track and furring channel. Maximum line speed of 210 feet per minute!

Wrap Rollformer Test

Form Process Engineering team testing a ‘Wrap” Rollformer, used in production line for fabricating mailboxes

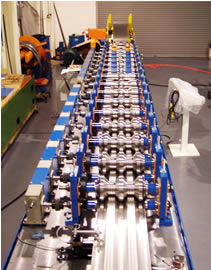

Steel Framing Roll Forming System

Production roll forming system built by Form Process Engineering team.

System has side by side tooling to make drywall stud, drywall track and furring channel.

Max line speed 210 feet per minute.

Purlin Structural Roll Forming Stud Line

Introduction To The Company & Our Roll Form Equipment

Roll Forming Equipment offers significant advantages to Manufacturers, and

Form Process Engineering has the experience to supply quality Roll form Systems.